Biotechnology and plastics technology

The innovation labs in the topic “Biotechnology and plastics technologies” develop microbial production strains and biotechnological protein products.

The research activities aim to develop biotechnological processes for diverse uses, for example in the areas of microplastic-free food, recycling of food waste, sustainable production of biopharmaceuticals and anchor peptides for reduced pesticide use and beneficial insect protection.

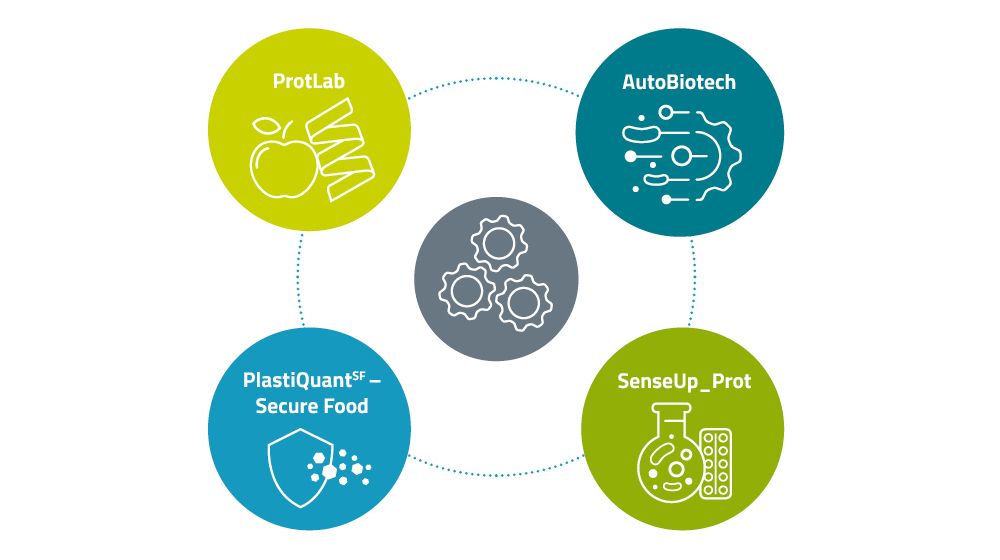

Four innovation labs are grouped in the topic “Biotechnology & plastics technologies”. All of them aim to have a structurally changing effect in the Rhenish mining region. They prepare the ground for job creation and contribute to the market maturity of innovative products and technologies.

Automated strain and bioprocess development

AutoBiotech: The innovation lab AutoBioTech is a technology platform for automating and digitizing microbial strain and bioprocess development to produce high-performance microbial strains as quickly and cost-effectively as possible.

Microplastic-free food through particle quantification

PlastiQuant: The innovation lab PlastiQuant is developing a high-throughput method using special proteins to detect, remove and recycle micro- and nanoplastics in drinking water, juices and aquaculture products.

Production platform for biopharmaceutical active ingredients

SenseUp_Prot: The innovation lab SenseUp_Prot develops a fermentation platform for the industrial production of pharmaceutical protein- and nucleic acid-based active ingredients for the production of e.g. vaccines, antibodies or bioinsecticides.

Tailored proteins for healthy food

ProtLab: The innovation lab ProtLab is working on the further development of the patented greenRelease technology using specialized anchor peptides for example for a reduced use of pesticides, bee health or sustainable film packaging.